Engineering the future

CNC Milling

Engineering the future

CNC Milling Services

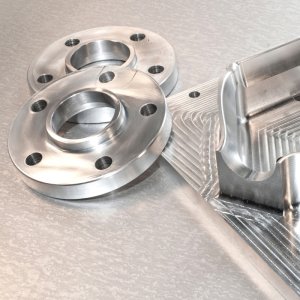

Introducing our CNC Milling Service featuring the cutting-edge HURCO VMX 42i machine!

Experience unparalleled performance and versatility with our VMX 42i machining centre from HURCO. Perfect for CNC machining on 3 axes, our machine offers:

- Efficient manufacturing of medium to large workpieces

- Exceptional rigidity and stability with linear guides in X, Y, and Z axes

- HURCO’s patented WinMax control MAX® 5, streamlining programming for heightened productivity

- Solid cast iron machine construction for enduring reliability

- A robust spindle featuring SK 40 tool holder, speeds up to 12,000 rpm, and a maximum spindle power of 18 kW

- Electrically driven tool changer with double gripper for seamless operation

Trust in our CNC Milling Service powered by the HURCO VMX 42i for precision, efficiency, and cost-effectiveness!

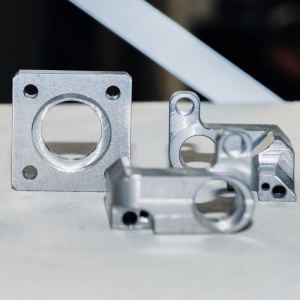

What is CNC Milling?

CNC milling is a high-tech way of shaping materials into precise parts. It uses computer controls to guide cutting tools, carving away excess material from a block to create the desired shape. This automation ensures accuracy and consistency, making it popular in industries like aerospace and manufacturing. CNC milling is essential for creating intricate designs efficiently, working with various materials like metals and plastics.

Why Choose MolloyEngineering?

Precision Engineering Excellence:

At MolloyEngineering, precision isn’t just a promise; it’s the cornerstone of our service. Our CNC milling expertise is underpinned by a relentless commitment to achieving exacting standards. Equipped with state-of-the-art HURCO technology and operated by highly skilled professionals, our machinery ensures unparalleled precision in every component we produce.

Efficiency Delivered on Time:

We believe that time is currency. We recognise this urgency and excel in delivering efficiency without compromise. Our optimised workflows and advanced equipment empower us to meet tight deadlines with ease. Whether it’s a small batch or a large-scale production run, expect your CNC-machined parts promptly and precisely, every time!

Assured Quality in CNC Milled Parts

With our ISO 9001 certification, we maintain stringent quality standards across the manufacturing process. Our commitment to excellence ensures that you receive nothing short of the finest service.

Trust us to fulfil your CNC milling project requirements within your specified deadlines and precise specifications. All this comes at a remarkably competitive price, making us your trusted partner for quality and affordability.

Tailored Solutions for Unique Needs:

Recognising the diverse nature of projects, We pride ourselves on offering customised solutions tailored to your specific requirements. Collaborating closely with clients, we delve deep into the intricacies of each project to deliver personalised outcomes whether it’s intricate designs, tight tolerances, or specialised materials, our adaptability and expertise guarantee solutions that surpass expectations, every time.

talk to us

Connect with

Joseph Berry

| Spindle nose – table (mm) | 152 – 762 |

| Table working surface W x D (mm) | 1.270 x 610 |

| T-Slots (DIN 650) | 5 x 18 x 100 |

| Load max. (uniform distribution) (kg) | 1.750 |

| X-Axis (mm) | 1.067 |

| Y-Axis (mm) | 610 |

| Z-Axis (mm) | 610 |

| Spindle Taper (DIN 69871 A) | SK40 |

| Spindle Speed max. (rpm) | 12.000 |

| Spindle Power (kW) | 18 |

| Spindle Torque max. (Nm) | 239 |

| Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min) | 38 / 38 / 32 |

| Number of stations | 30 / 40 |

| Tool diameter max. (mm) | 80 / 76 |

| Tool length max. (mm) | 300 |

| Tool weight max. (kg) | 7 |

let’s get connected

Have a Question?

Don’t hesitate to get in touch with us via email or phone. Our team is always ready to assist you and provide you with the best solution for your needs.