Engineering the future

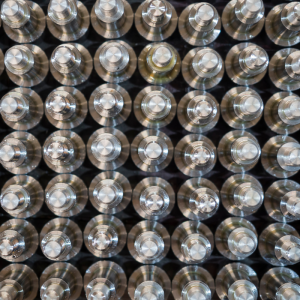

CNC Turning

Engineering the future

CNC Turning Services

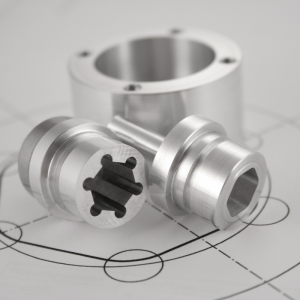

We use advanced Doosan turning technology for comprehensive automation, high-speed performance, and exceptional precision. Our skilled operators expertly handle complex CNC-turned parts and large-scale production with expertise. With advanced machinery, we make precise components from various metals and steel. Trust our precision CNC turning method for outstanding results, delivered promptly to advance your project.

What is CNC Turning?

CNC turning with Doosan technology is the precise shaping of cylindrical parts using computer-controlled lathes made by Doosan. It involves setting up the workpiece, programming the machine, selecting cutting tools, and then letting the lathe cut the material to the desired shape. Doosan machines offer advanced features for efficiency and accuracy in manufacturing.

Why Choose MolloyEngineering?

Precision Engineering:

Benefit from our experience and expertise in precise machining, powered by state-of-the-art Doosan CNC lathes, ensuring accuracy to the most exacting standards.

Efficiency and Innovation:

Our production processes are streamlined without compromising on quality, utilising advanced Doosan-powered CNC machines that ensure rapid turnaround times and economical solutions.

Versatile Manufacturing:

From initial prototypes to full-scale production, our CNC turning capabilities feature highly stable and exceptionally productive gang-type turning centres from Doosan technology. This allows us to handle a diverse array of materials and complex tasks, providing the flexibility to meet various requirements.

Trusted Partnership:

Trust our dedicated team for exceptional service and support throughout your project, prioritising your satisfaction and delivering successful outcomes. Choose MolloyEngineering for unmatched quality, efficiency, and reliability in CNC turning.

talk to us

Connect with

Joseph Berry

| Chuck size | 6 inch |

| Max. Turning Diameter | 170 mm |

| Max. Turning Length | 330 mm |

| X-Axis Rapid Traverse | 30 m/min |

| Z-Axis Rapid Traverse | 36 m/min |

| X-Axis Travel Distance | 450 mm |

| Z-Axis Travel Distance | 340 mm |

| Max. Spindle Speed | 6000 r/min |

| Max. Spindle Power | 18.5 kW |

| Max. Spindle Torque | 118 N.m |

let’s get connected

Have a Question?

Don’t hesitate to get in touch with us via email or phone. Our team is always ready to assist you and provide you with the best solution for your needs.